Semiconductor technology is developing rapidly. With continuous miniaturization, increased performance and ever higher integration densities of components, chips are becoming ever more powerful. However, these advances also bring with them new challenges - particularly in the area of thermal management. Higher clock frequencies and ever more compact designs lead to increased power loss, which is why dissipating the heat generated on the PCBs is becoming increasingly important.

The development of semiconductor technology: from 1000 to 50 billion transistors

An impressive example of this technological development can be seen in the number of transistors on a chip. In the 1970s, the first Intel chips had around 1000 transistors. Nowadays, up to 50 billion transistors are integrated on modern high-performance chips. This high number of transistors means more power in a smaller space, but this also leads to higher power loss. Without effective thermal management, system performance is compromised and board reliability decreases.

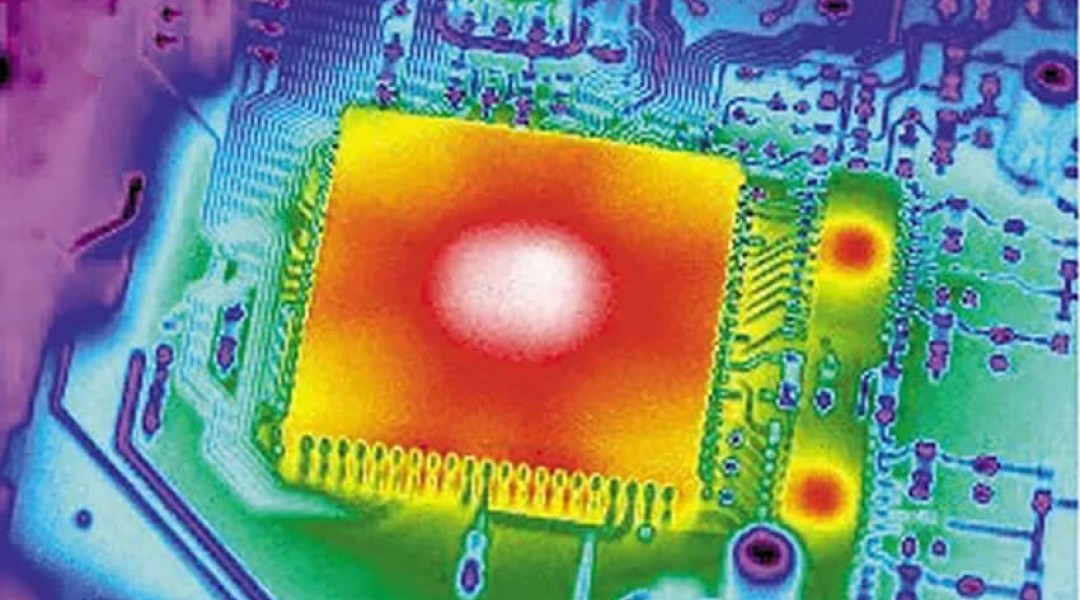

Thermal management: the key to system performance

Sophisticated thermal management is crucial to meet the increasing demands of semiconductor technology. Insufficient heat dissipation can reduce system performance, damage components and shorten service life. With the right solution, system performance and reliability can be optimized - whether through improved high current capability, maximum heat dissipation or a combination of different requirements.

Our heat management solutions: Tailor-made concepts for your requirements

We offer you a wide range of thermal management solutions that are specially tailored to the needs of your applications:

Metal core PCBs: This technology helps to efficiently dissipate heat generated away from sensitive components and optimize PCB cooling.

PCBs with embedded copper coins: This solution ensures improved heat dissipation with high power density.

Thick copper boards with up to 400µm copper/layer: These boards offer even more effective heat dissipation, especially for power-optimized applications.

Insulated Metal Substrates (IMS): The combination of insulators and metals efficiently dissipates heat and reduces the temperature in the components.

Copper-filled microvia holes: This technology improves heat conduction and is ideal for compact, highly integrated circuits.

Global success through innovative thermal management solutions

Varioprint supplies leading global companies in various industries that rely on advanced thermal management solutions:

Industrial electronics: for high-performance applications in manufacturing and industrial automation.

Aerospace and defense: Where the highest demands are placed on reliability and temperature stability.

Mobility: For the development of high-performance systems in the vehicle and mobility industry.

Telecommunications: For ensuring stable performance in networks and communication systems.

The right thermal management is a key factor in the performance of modern systems. The development of ever more powerful chips requires customized thermal management solutions that meet the increasing requirements. With our innovative technologies, we help you to maximize system performance while ensuring the reliability and service life of your products. Rely on the expertise of our Varioprint specialists to find the best solution for your business and your requirements.