High-frequency PCBs, precision and innovation for the highest demands

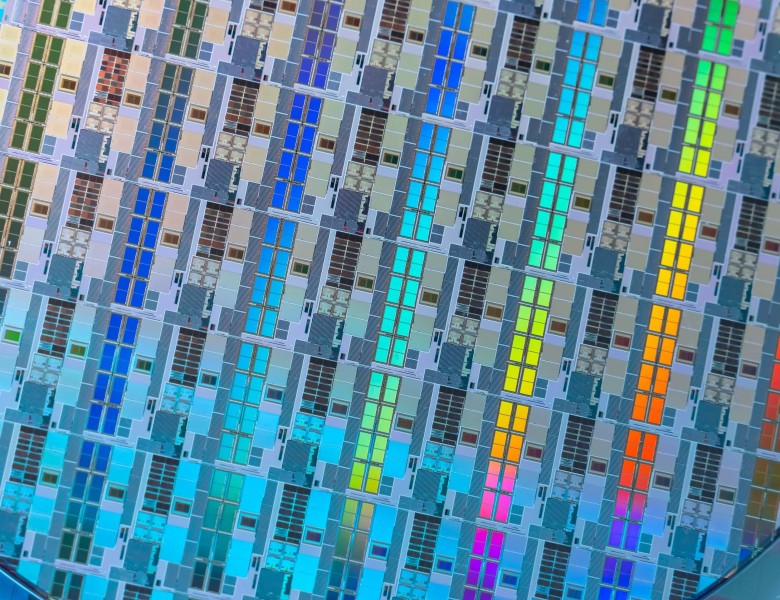

We are one of the leading global suppliers in the manufacture of high-frequency PCBs. Our expertise includes the production of multilayer circuits made of Teflon (PTFE), which can be manufactured using fusion bonding, as well as constructions with mixed materials such as FR4 and PTFE. Embedded heatsinks and stably controlled process parameters are standard for us to guarantee consistently high quality – even with high production volumes.

In close cooperation with renowned material suppliers such as Rogers, Taconic and Neltec, we offer a unique range of services for your high-frequency applications. Our specialist engineering team supports you in the selection of suitable materials and in the structure and design of your PCB.

For sophisticated high-frequency solutions between 77–79 GHz, especially for applications such as radar systems in the mobility industry, we offer customised processes that guarantee the highest RF performance and maximum reliability. Rely on our expertise and power of innovation to realise your high-frequency performance requirements at the highest level.

Range of services

Structure and technology

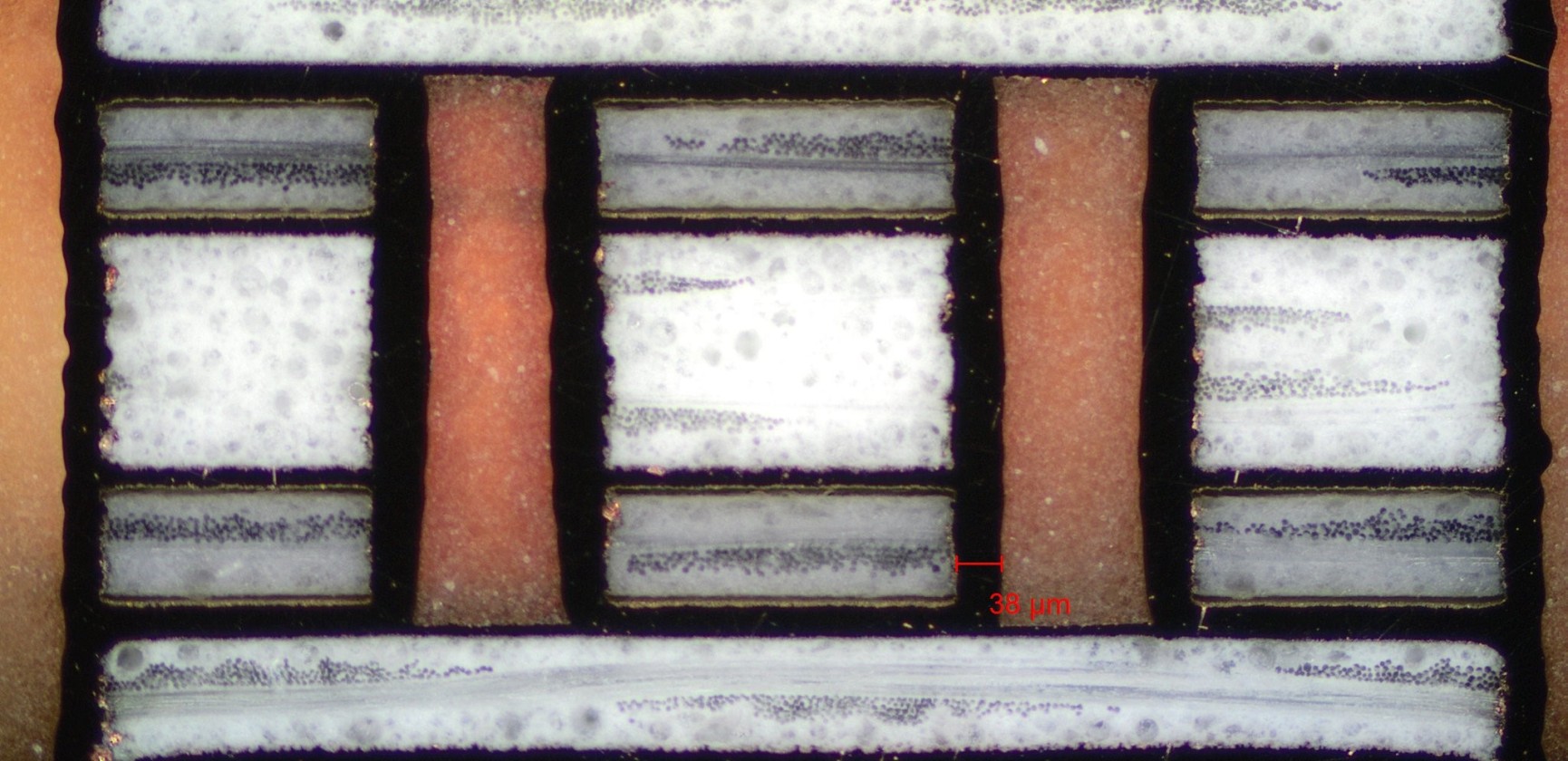

Multilayer and mixed structure circuits, PTFE fusion bonding, heatsink technology and pure PTFE softboards

Blind vias, buried vias, µvias with and without copper filling as well as plugged bore holes with/without overplating

Dimension and formats

Thickness 0.2 mm to 4.8 mm thickness

Format up to 569x490 mm

Used panel formats 460x610 mm and 530x610 mm

Coatings and additional prints

Photosensitive solder mask in various colours using spray and screen printing processes

Solder mask registration

Standard: +–50 µm

Special: +–25 µm

Additional prints such as labelling print, peel-off mask and carbon print

Circuit pattern structuring

Copper claddings from 18 µm to 210 µm

Conductor widths and spacing

Standard: 75 µm/100 µm

Special: 50 µm/50 µm

Etching tolerances

Standard: +–20 µm

Special +–10 µm

Mechanical processing

Contour milling

High-precision deep routing for cavities and waveguide connections

Scoring

Laser processing

Annular rings

Standard: 100 µm

Special: 75 µm

Materials

HF substrates from all common manufacturers such as Rogers, Taconic, Neltec or Isola, e.g. RO3003 or NY-9220 as well as many other materials

In addition to core materials, all common HF bondplies such as RO4450, Gore Speedboard or Taconic Fastrise can also be laminated

End surfaces

Various chemical and galvanic gold surfaces as well as chemical tin and chemical silver surfaces and pure organic protective lacquers

Nickel-free surfaces are also available, which are particularly important for HF technology

Electroplating and copper plating

Aspect ratio up to 1:12 with 0.15 mm drill diameter

1:15 with 0.3 mm drill diameter

Copper in vias according to IPC 2, IPC 3 or customised

Thanks to state-of-the-art electroplating processes, very even copper distribution on the panel and thus a precise etching tolerance is achieved