Metal core PCBs, efficient thermal management for maximum reliability

Varioprint offers first-class metal core PCBs that increase the performance and reliability of electronic systems through efficient thermal management. With a variety of technologies and solution concepts, we ensure optimum heat dissipation and thus support the longevity and stability of your applications.

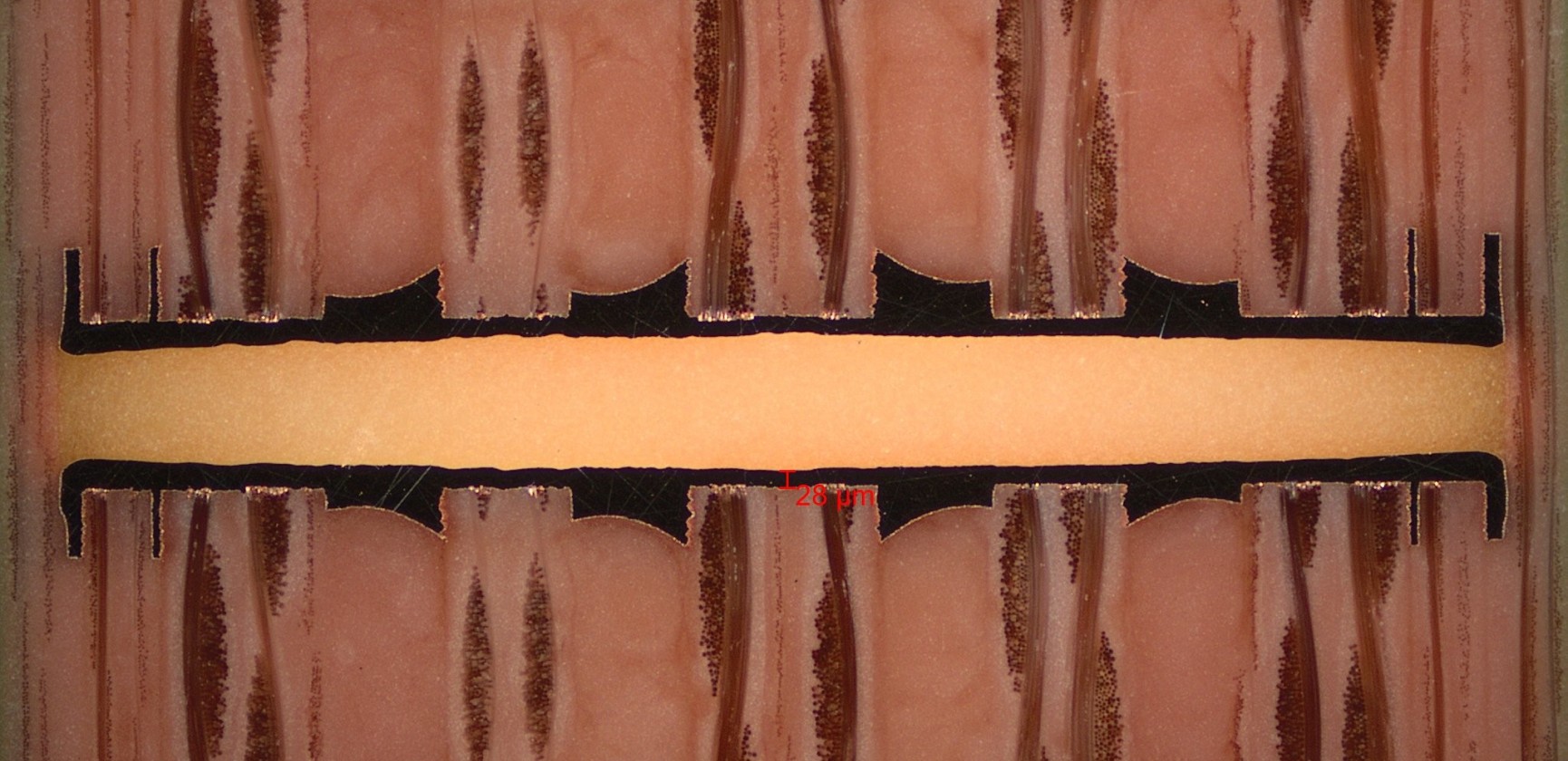

Our metal core PCBs consist of full-surface elements made of copper, brass or aluminium. In addition, partial inlays, so-called "coins", enable targeted heat dissipation. We maximise the cooling surface and ensure effective heat transfer through precise deep routing and flank metallisation. This optimised thermal management not only reduces overall costs, but also increases the reliability of your systems.

Thanks to state-of-the-art production technologies, including specialist drilling and milling machines for metalworking, we deliver high-quality and innovative solutions that are tailored to the requirements of modern electronics. Varioprint is known for its metal core PCBs that provide maximum precision and efficiency.

Range of services

Structure and technology

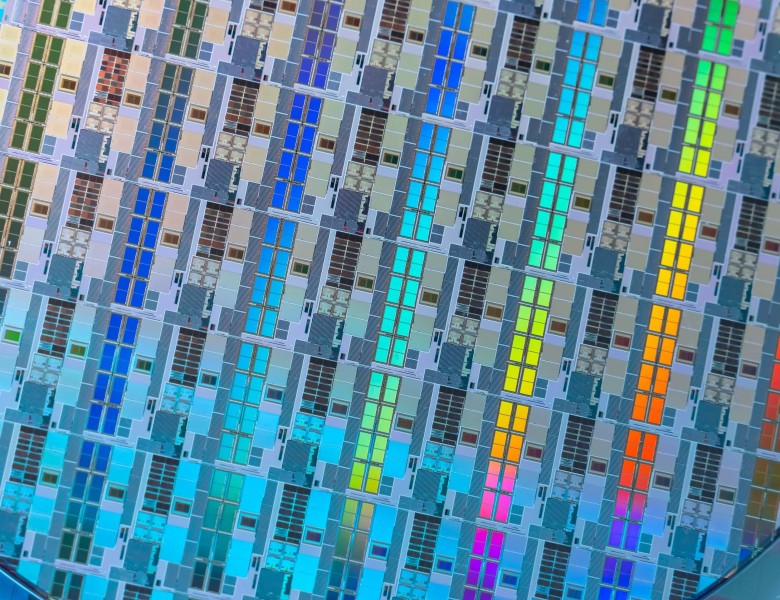

Circuits on pre-pressed metal core substrate made of copper, brass or aluminium or inlaid copper cores in the PCB

Blind vias, µvias with and without copper filling as well as plugged vias and insulated through-plated vias in the metal body

Dimension and formats

Thickness up to 4.8 mm including metal core

Format up to 265x419 mm (usable area)

Utilised panel format 305x460 m

Coatings and additional prints

Photosensitive solder mask in various colours using spray and screen printing processes

Solder mask registration

Standard: +–50 µm

Special: +–25 µm possible

Additional prints such as labelling print, peel-off mask and carbon print

Circuit pattern structuring

Copper claddings from 18 µm to 210 µm

Conductor widths and spacing

Standard: 75 µm/100 µm

Special: 50 µm/50 µm

Mechanical processing

Contour milling

High-precision deep milling

Laser-cut MMIC pockets or cavities

Annular rings

Standard: 100 µm

Special: 75 µm

Materials

PTFE substrates with pre-pressed copper or brass core – Embedded copper cores and substrates on subsequently pressed heatsinks (post-lamination) and thermally conductive special materials such as Bergquist or Laird

End surfaces

Various chemical and galvanic gold surfaces as well as chemical tin and chemical silver surfaces and pure organic protective lacquers

Electroplating and copper plating

Aspect ratio up to 1:15 with 0.3 mm drill diameter

Copper in the bore holes according to IPC 2, IPC 3 or customised