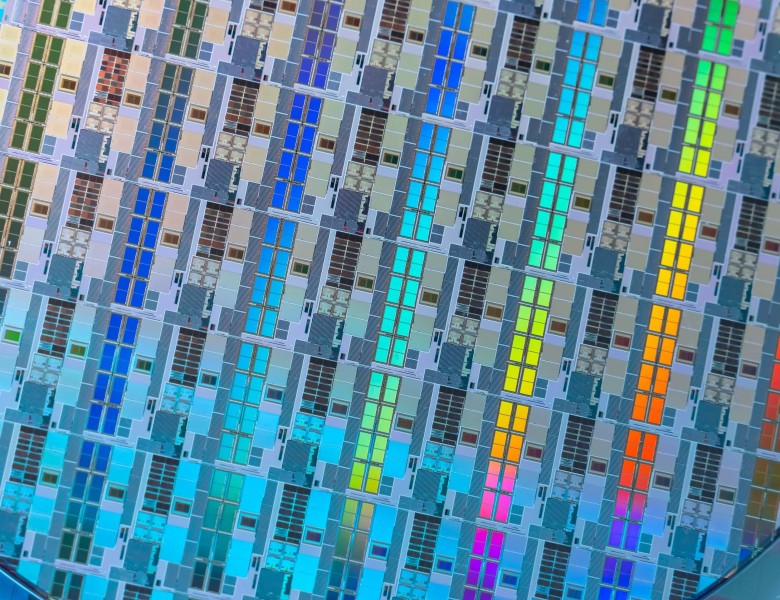

Multilayer and HDI PCBs, high-precision solutions for state-of-the-art electronics

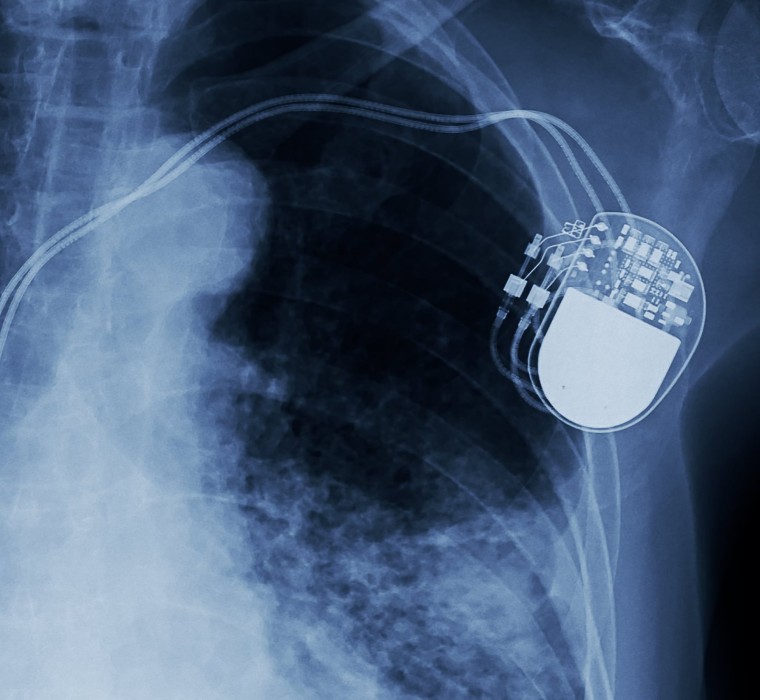

Multilayer and HDI PCBs from Varioprint are the answer to increasing demands for miniaturisation, high packing densities and optimised signal integrity. With over 35 years of expertise in multilayer circuit manufacturing, we offer products that guarantee the highest quality and reliability. Thanks to optimised automated processes, precise registration and state-of-the-art via technologies, our PCBs meet the most demanding technical requirements.

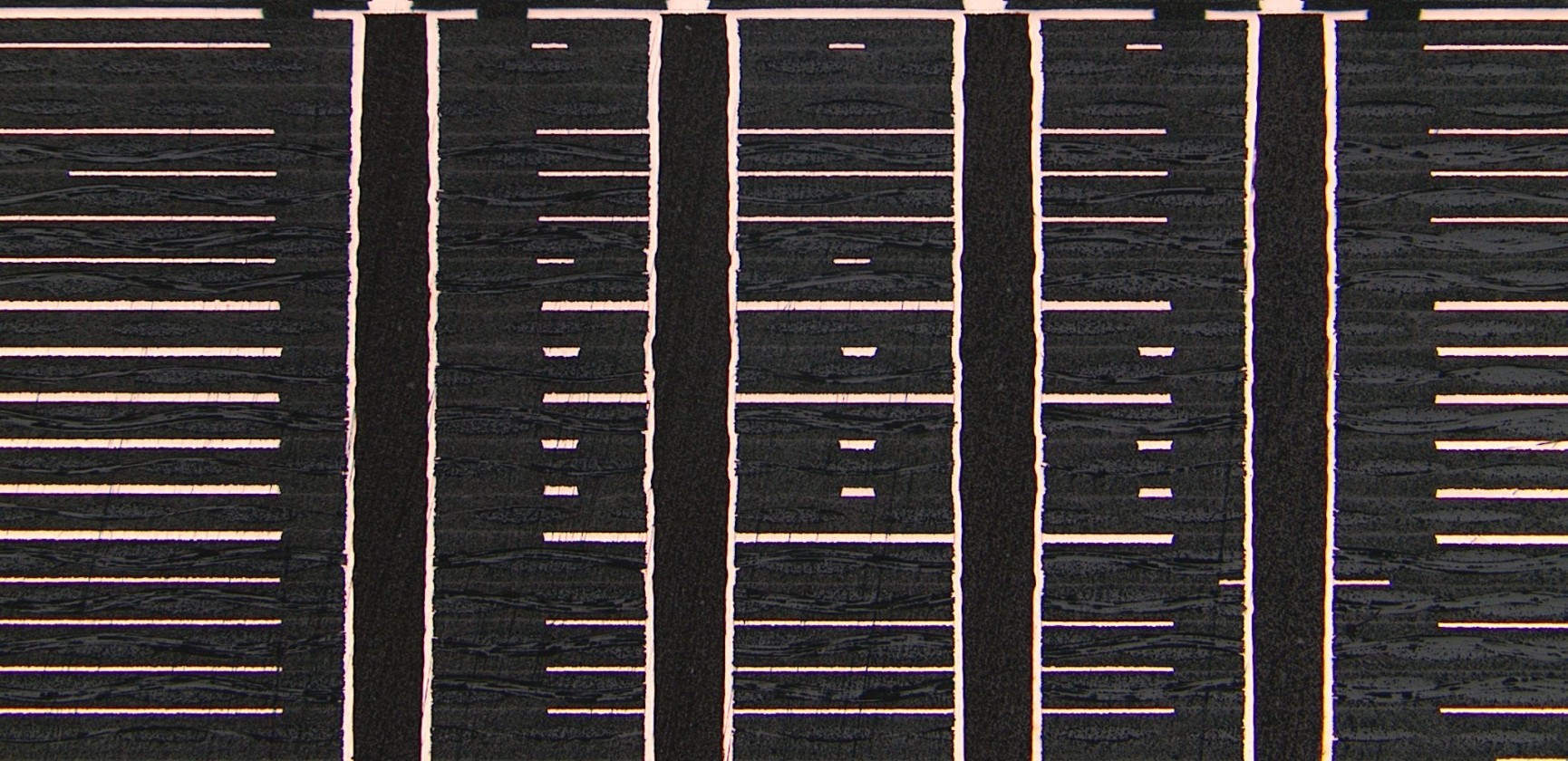

The development of ultra-thin cores with a thickness of just 50 µm, ultra-fine structures and an increasing number of layers make our multilayer and HDI solutions the standard for modern assemblies. Our PCBs efficiently separate analogue and digital areas and enable maximum functionality in the smallest possible space thanks to integrated blind and buried vias as well as copper-filled µvias.

With our high-precision laser drilling systems and our state of the art vertical electroplating equipment, we offer maximum process stability and highest quality standards. Varioprint stands for innovation and expertise in the development of multilayer and HDI PCBs that fulfil tomorrow's requirements today.

Range of services

Structure and technology

Multilayer and HDI circuits of up to 28 layers with a wide range of materials

Blind vias, buried vias, µvias with and without copper filling as well as plugged bore holes with/without vias

Dimension and formats

Thickness 0.2 mm to 4.8 mm thickness

Panel usage up to 569x490 mm

Used panel formats 460x610 mm and 530x610 mm

Coatings and additional prints

Photosensitive solder mask in various colours using spray and screen printing processes

Solder mask registration Standard: +–50 µm Special: +–25 µm possible

Additional coatings such as labelling print, peel-off mask and carbon print

Circuit pattern structuring

Copper claddings from 18 µm to 210 µm

Conductor widths and spacing

Standard: 75 µm/100 µm

Special: 50 µm/50 µm possible

Mechanical processing

Contour milling

Deep routing

Scoring

Laser processing

Remaining rings

Standard: 100 µm

Special: 75 µm

Materials

FR4, Tg 135 °C fillers

FR4 high Tg 170 °C

Halogen-free materials

PTFE materials

Special materials

Standard glass fabric type 106/1080/2116 and 7628, others available, depending on requirements and structure

End surfaces

Various chemical and galvanic gold surfaces as well as chemical tin and silver surfaces and pure organic protective finishes

Electroplating and copper plating

Aspect ratio up to 1:12 with 0.15 mm drill diameter, 1:15 with 0.3 mm drill diameter

Copper in vias according to IPC 2, IPC 3 or customised