Flex and rigid-flex PCBs, versatility for demanding applications

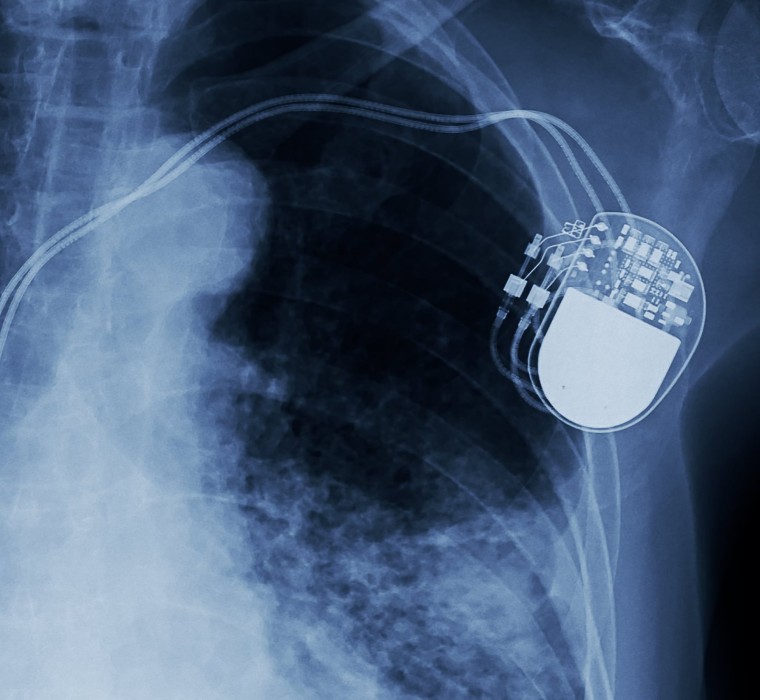

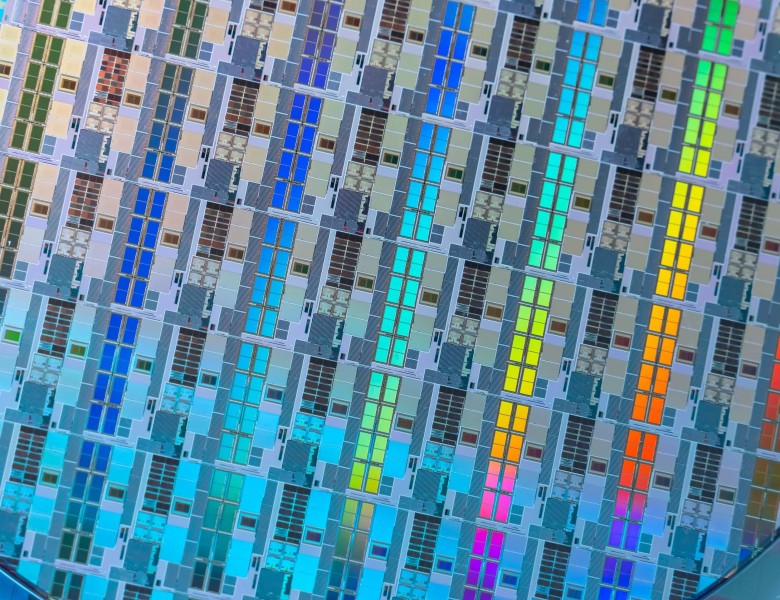

Flex and rigid-flex PCBs from Varioprint offer an innovative solution for modern connection technologies. Thanks to their high versatility and reliability, they have established themselves in sectors such as aerospace, defence, medical technology and industrial electronics. This technology enables assemblies to be designed more reliably, assembly costs to be minimised and space to be used effectively.

Our flex and rigid-flex PCBs are tailored to your requirements, whether for dynamic bending, space constraints, or continuous flexing stress. They are the ideal choice when it comes to connecting moving components or complex geometries. Varioprint stands for the highest quality – from prototypes to series production.

Our experienced engineering team supports you in every phase of your project and helps to realise your requirements efficiently and precisely. Rely on Varioprint for reliable and innovative flex and rigid-flex PCB solutions.

Range of services

Structure and technology

Multilayer circuits with symmetrical and asymmetrical design, semi-flex (static bending cycles for assembly) and full-flex design (for dynamic bending cycles) in a wide range of materials

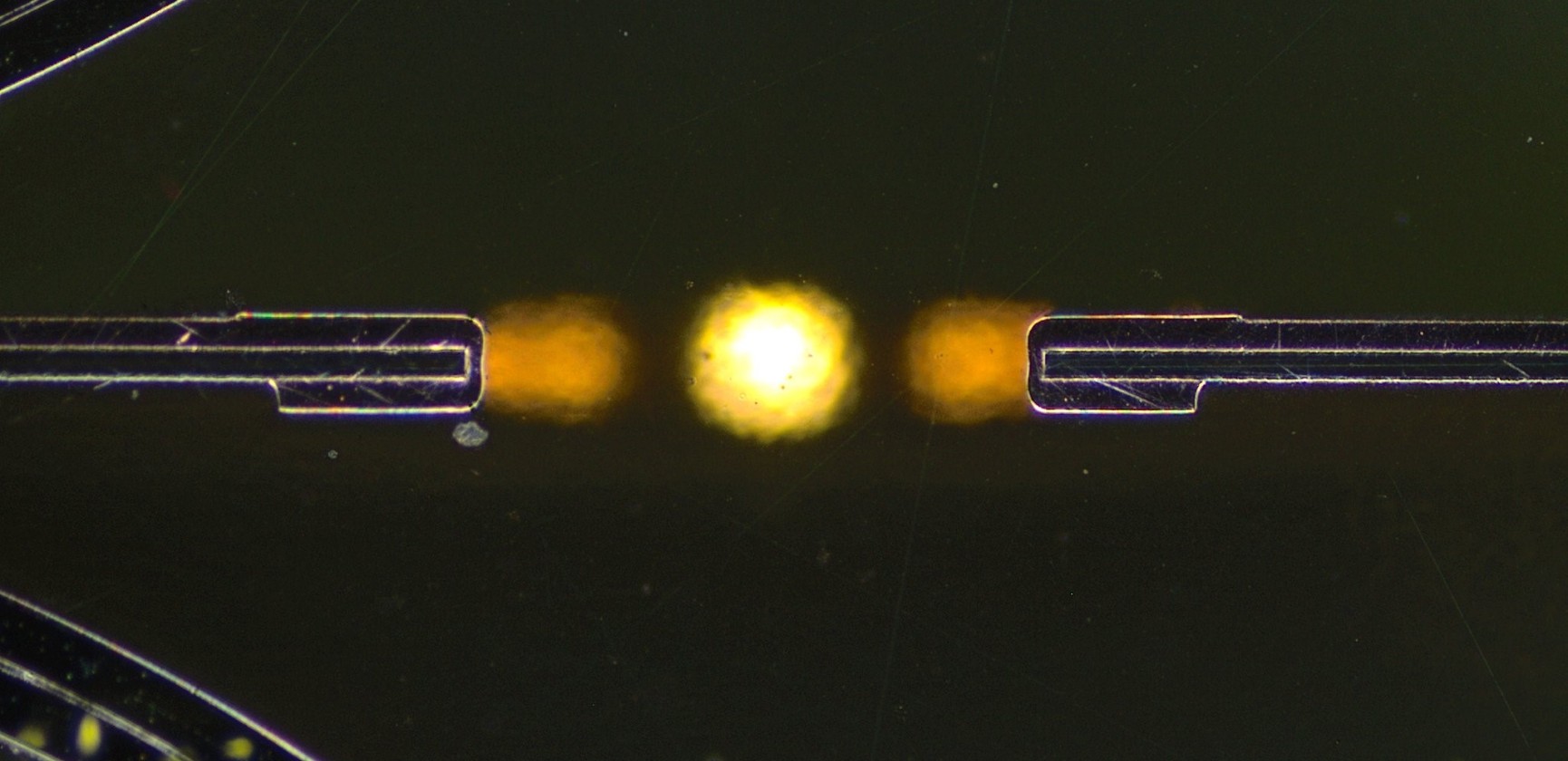

Blind vias, buried vias, µvias with and without copper filling as well as plugged via with/without overplating

Dimension and formats

Thickness 0.1 mm to 4.8 mm thickness

Panel formats used

305x460 mm and 460x610 mm

Usable area up to 420x69 mm

Coatings and additional prints

Photosensitive solder mask in various colours using spray and screen printing processes

Solder mask registration

Standard: +–50 µm

Special: +–25 µm

Additional coatings such as labelling print, peel-off mask and carbon print

Circuit pattern structuring

Copper claddings from 18 µm to 210 µm

Conductor widths and spacing

Standard: 75 µm/100 µm

Special: 50 µm/50 µm

Mechanical processing

Contour milling

Deep routing

Scoring

Laser processing

Annular rings

Standard: 100 µm

Special: 75 µm

Materials

Tg 135 °C and high Tg 170 °C FR4

Halogen-free materials

PTFE materials

Polyimides (Kapton) and special materials such as LCP (liquid crystal polymers)

End surfaces

Various chemical and galvanic gold surfaces as well as chemical tin and silver surfaces or pure organic protective lacquers

Electroplating and copper plating

Aspect ratio up to 1:12 with 0.15 mm drill diameter

1:15 with 0.3 mm drill diameter

Copper in vias according to IPC 2, IPC 3 or customised