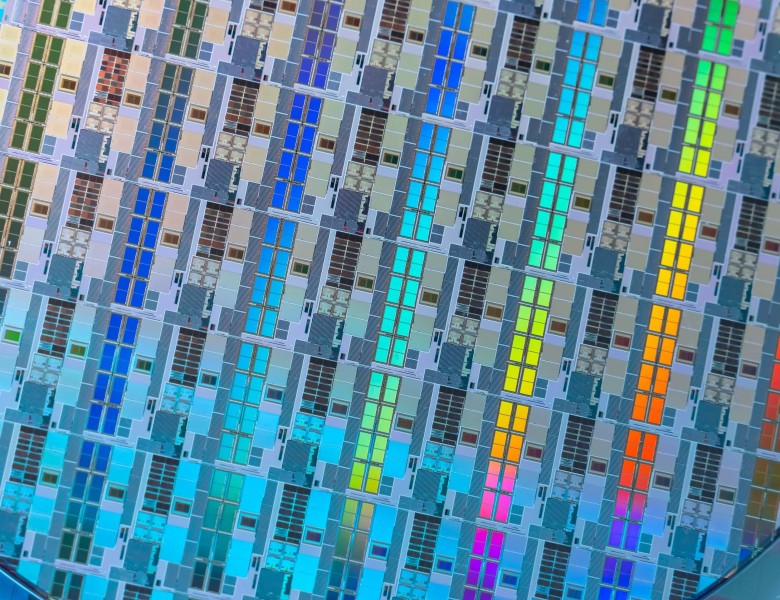

Does the term through hole filling mean anything to you? Have you ever thought about using copper-filled holes, also known as through hole filling? If not, we'll explain in this blog post what copper-filled holes are all about and three reasons to consider this technology.

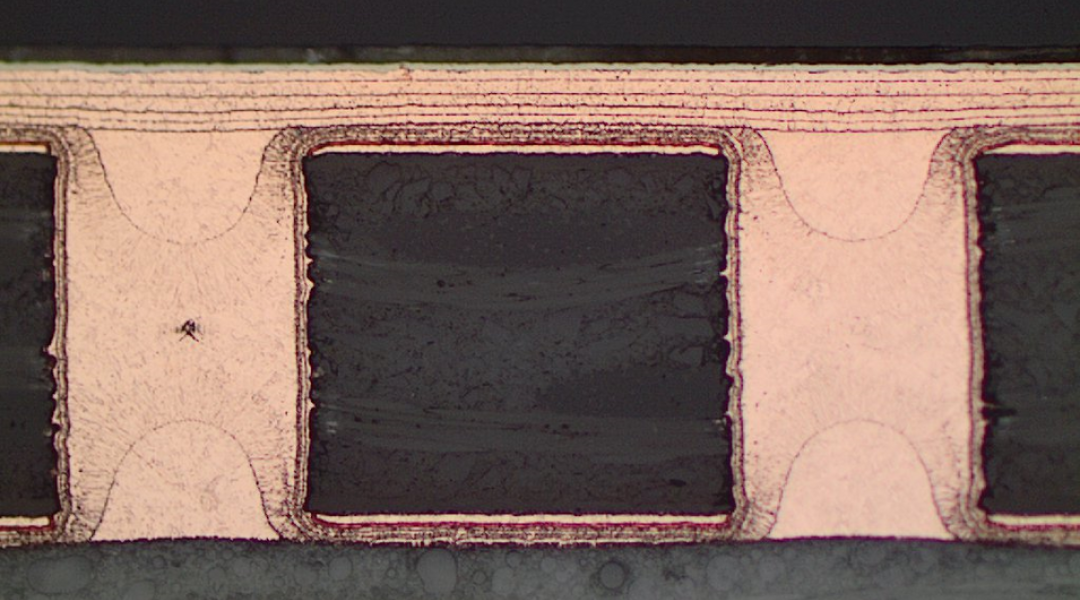

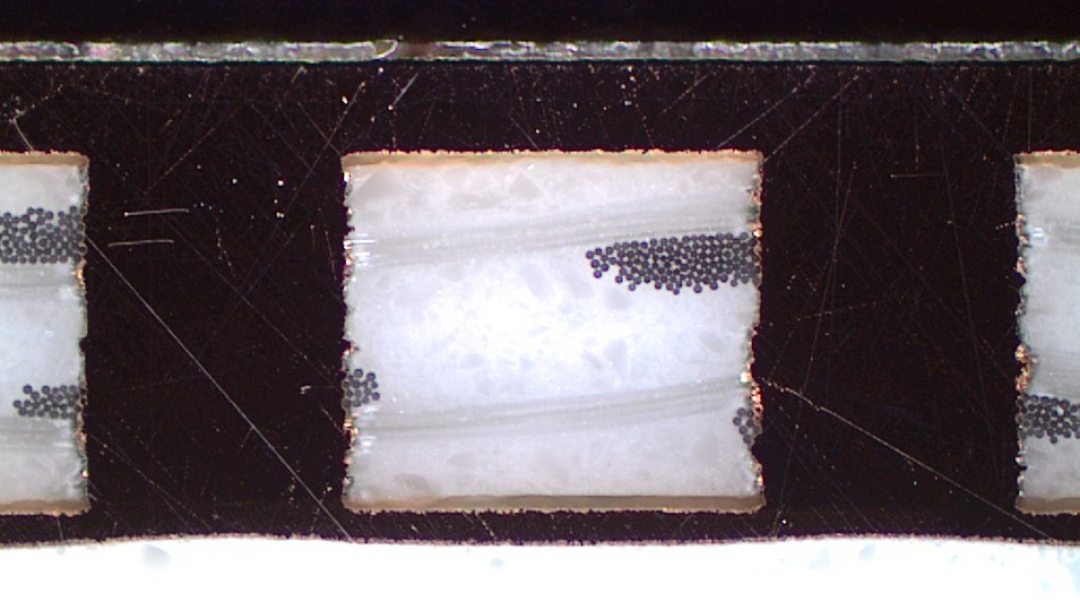

THF is a new plating technology and stands for Through Hole Filling (filling through holes with electrolytic copper). This two-stage process makes it possible to achieve complete copper filling of through holes, whereby the increase in copper layer thickness on the surface is minimal in comparison. Copper-filled holes offer numerous advantages. This applies in particular to the high-frequency range. In our blog, we show you three good reasons to use copper-filled holes.

Fewer losses

Actually, the first reason would almost be enough to at least consider copper-filled holes: fewer losses. Copper-filled holes enable a reduction in contact resistance, which leads to improved power transfer. The higher conductivity of the copper minimises the resistance at the connection points.

Fewer faults

Copper-filled holes allow for lower capacitance and better matching. But why is this relevant? In the high-frequency range, a lower capacitance has a positive effect on the signal propagation time in the time domain. The improved matching also leads to a reduction in electromagnetic radiation in the frequency range. Exactly the interference you want to avoid on the circuit board.

Higher electrical and thermal conductivity

The copper-filled holes are much more suitable for high-power, microwave or LED applications due to their higher electrical and thermal conductivity.

As a manufacturer of complex PCBs, at Varioprint we welcome enquiries regarding copper-filled holes. With our expertise and experience in PCB manufacturing, we offer high-quality solutions that exceed our customers' requirements.

Would you like to find out more about this topic? Then feel free to contact us with your questions. With a future-orientated and long-term innovation policy, the latest process technologies and the highest possible level of automation, we are always one step ahead.